Dec 19, 2017 - The challenges of high pressure have kept metal 3D printing from gaining widespread application in hydraulics technology, but we may begin seeing 3D-printed components in specialized applications.

One advantage of hydraulics technology is its high power density. Hydraulic pumps are typically a small fraction the size of the electric motors that drive them, and the size and weight differential between pumps and gas or diesel engines is even more pronounced. An even bigger advantage is with actuators. Hydraulic cylinders only a few inches in diameter can generate forces to lift thousands of pounds, crush rock and concrete, or form high-strength steel into rugged components.

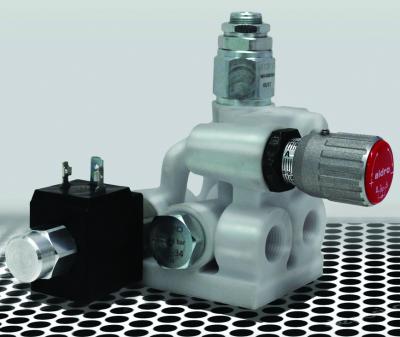

Of course, another advantage of hydraulics is its ability to control direction, speed, torque, and force using anything from simple manually operated valves to sophisticated electronic controls to command valves automatically. And even though electronic control of hydraulic valves continues to advance, processes improvements for manufacturing the valves themselves have not been as dramatic. But that has started to change.

Where We Are and May Be Going

Cartridge valve technology is widely used to integrate several control functions into a single manifold. Centrally locating multiple valves within a manifold can dramatically reduce

Continue here to read the full article written by Alan Hitchcox for Hydraulics & Pneumatics Hydraulics & Pneumatics || December 14, 2017 |||