President of UK Football Foundation now takes Five Questions.....

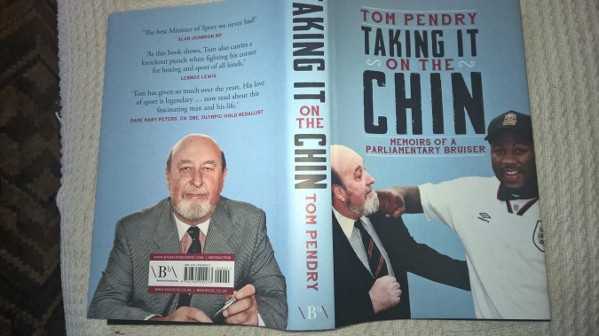

Lord Pendry is familiar in New Zealand within sporting circles. He retains too a constant guardian-angel like role over the nation, most recently when in the House of Lords he challenged the Government over the need to control the validity of labelling for Manuka honey. He was for many years the Labour Member of Parliament for Stalybridge and Hyde. In 2000, he was appointed member of the Privy Council on the recommendation of Tony Blair. After the 2001 election he was elevated to the peerage as Baron Pendry of Stalybridge. An institution within the English speaking realm’s greatest institution, the Palace of Westminster, boxing buff Lord Pendry (above) has just seen published his autobiography, Taking It On The Chin (see below).

You began your career as an engineer. How important is a manufacturing-production base for a developed economy such as Britain’s or New Zealand’s for that matter?Although the service industries are increasingly the norm in Britain, manufacturing continues apace; the UK is currently the world's ninth largest industrial nation. I think it is important that the Government does more to support UK manufacturing industries despite fierce competition from other countries. The recent crisis with steel production in South Wales is a case in point.

As a British Member of Parliament you knew the Blair family, from Tony’s father-in-law, who lived in your constituency, and you were widely credited with opening the path to Westminster for Tony. His legacy?Yes, I introduced Tony Blair into mainstream parliamentary politics in 1982 when, following my introduction, he unsuccessfully fought a by-election before gaining a safe seat in the North East constituency of Sedgefield. In my view, Tony was an outstanding Prime Minister who achieved much, especially bringing peace to Northern Ireland, but many other good measures also—regretfully he will be remembered by many for his support of the Iraq invasion.

Your constant advocacy for sport is well-known. How important in the age of video games is organised sport for school age boys and girls?Sport within society is of great importance to both the health and morale of its people but also in its importance to the economy of countries like the UK and New Zealand. Sport is also a great leveller in terms of gender, religion and race, bringing together the best in humankind. In order to address the negative effects of children playing video games, it is important that sport facilities are provided and participation in sport is encouraged. A good example of an organisation in the UK which invests in local sport facilities is the Football Foundation, of which I am President; with funding from the Government, the FA and the Premier League, the foundation funds multiple projects across the UK which provide new and refurbished grassroots sports facilities, improving the quality and experience of playing sport at the grassroots level. Formed in 2000 they have supported projects worth more than £1.3 billion.

One sport you most definitely do not approve of is fox-hunting?Certainly I do not approve not only of fox hunting but of cruelty to animals per se. Fox hunting is now illegal in the UK but there is evidence to suggest that hunts continue to take place. The argument that fox hunting is about curbing the number of foxes in the wild—a form of pest control—does not stand up because there is strong evidence to show that foxes have been captured and bred by hunters purely to be used in hunts.

You have on several occasions registered your disapproval of hereditary ascendancy to your own House of Lords?I do not believe that because a person achieved greatness in his lifetime that should also necessarily be reflected in the shape of a family member years later, who may not be worthy of the honour himself. We have in the House of Lords many examples of such people not worthy of the honour which had been bestowed upon their ancestor. Fortunately some do make a notable contribution to the workings of Parliament. In truth, now the number of hereditary peers is limited to 92 so some progress has been made in the right direction.

Immigration Minister Michael Woodhouse today announced a package of changes designed to better manage immigration and improve the long-term labour market contribution of temporary and permanent migration.

“The Government is committed to ensuring inward migration best supports the economy and the labour market,” Mr Woodhouse says.

“It’s important that our immigration settings are attracting the right people, with the right skills, to help fill genuine skill shortages and contribute to our growing economy.

“That is why we are making a number of changes to our permanent and temporary immigration settings aimed at managing the number and improving the quality of migrants coming to New Zealand.”

Changes to permanent immigration settings include introducing two remuneration thresholds for applicants applying for residence under the Skilled Migrant Category (SMC), which will complement the current qualifications and occupation framework.

“One remuneration threshold will be set at the New Zealand median income of $48,859 a year for jobs that are currently considered skilled. The other threshold will be set at 1.5 times the New Zealand median income of $73,299 a year for jobs that are not currently considered skilled but are well paid,” Mr Woodhouse says.

“The SMC points table, under which individuals claim points towards their residence application, will also be realigned to put more emphasis on characteristics associated with better outcomes for migrants.

“Collectively these changes will improve the skill composition of the SMC and ensure we are attracting migrants who bring the most economic benefits to New Zealand.”

The Government is also proposing a number of changes to temporary migration settings to manage the number and settlement expectations of new migrants coming to New Zealand on Essential Skills work visas.

The changes include:

“I want to make it clear that where there are genuine labour or skills shortages, employers will be able to continue to use migrant labour to fill those jobs,” Mr Woodhouse says.

“However, the Government has a Kiwis first approach to immigration and these changes are designed to strike the right balance between reinforcing the temporary nature of Essential Skills work visas and encouraging employers to take on more Kiwis and invest in the training to upskill them.

“We have always said that we constantly review our immigration policies to ensure they are fit for purpose and today’s announcement is another example of this Government’s responsible, pragmatic approach to managing immigration.”

Public consultation on the changes to temporary migration settings closes on 21 May, with implementation planned for later this year.

For more information visit:

www.immigration.govt.nz/about-us/media-centre/news-notifications/skilled-migrant-category-changes

New Zealand Trade and Enterprise (NZTE) has launched a new service designed to help early-stage exporters learn the fundamentals of becoming a successful export business.

NZTE’s new service, Export Essentials, consists of two parts. There are ten online guides that cover the basics of exporting that businesses can work through in their own time and pace. There is also a hands-on, collaborative two-day workshop, where participants will learn proven methods for successful exporting and leave with practical tools that they can apply directly to their business.

“We’re really excited to add Export Essentials to our range of services. I believe this answers a real gap in the market for exporters to learn practical tools to create a go to market plan, alongside fellow exporters’” said Suzie Marsden, NZTE General Manager for Services.

“New Zealand has approximately 12,000 exporting companies but about 11,000 of these earn less than $5 million a year in international revenue, so there’s a real opportunity to help some of these companies be more successful internationally,” she said.

“Export Essentials is designed to help companies who are in the early stages of exporting build their export awareness, readiness and capability. The online guides walk companies through everything from market validation and research to pricing, and the workshops will help participants to develop an export plan and learn proven approaches for global growth.”

“Building an international business from New Zealand is tough and we see a lot of Kiwi companies turning up in-market without being as prepared as they could be. We created Export Essentials with the aim that in time more companies will arrive in-market better prepared, better equipped and more likely to succeed in competitive international markets,” she added.

“We’ve worked closely with our industry partners who also support exporting companies to make sure the services we offer are complementary and not a duplication of what’s already available.”

“We also undertook a lot of testing with some of our current customers to develop the right content for these guides and workshops so I’m confident that Export Essentials will make a tangible difference to some early-stage exporters who are unsure of where to go for help or information,” said Ms Marsden.

The Export Essentials online tools and resources are free to access, and are part of a wider range of refreshed information, tools and resources on NZTE’s website. The workshops are co-funded by NZTE, with a contribution of $1,000+GST per attendee for the two days and follow-up session with the course provider. Export Essentials workshops for 2017/18 will be in five centres around New Zealand: Auckland, Napier, Wellington, Nelson and Christchurch.

For more information about Export Essentials, to register for a workshop, or to find out more about the benefits of becoming an NZTE customer, visit www.nzte.govt.nz/events/export-essentials-workshops

| An NZTE release || April 19, 2017 |||

Graffiti littering never ceases to be a problem with managers of buildings and public spaces constantly on the look-out for cost effective solutions. Solar Gard who are specialists in this field offer a variety of graffiti protection solutions to suit a wide range of applications:

GraffitigardActs As a Sacrificial BarrierGraffitigard protective film is a durable, optically clear and removable product that acts as a sacrificial barrier between vandals and the surfaces they deface. It is easily applied to interior and exterior glass windows and mirrors, as well as other non-porous surfaces like stainless steel and marble.Protects from: paint, key scratches, marking and even acid-etching.Download Graffitigard flyer here

GraffitiTidyProtects Surfaces, Allowing Speedy and Efficient Clean-UpGraffitiTidy is a durable, clear film with a non-stick outer surface suitable for applying to smooth surfaces to protect against graffiti damage from marker pen and spray paint. Once pen and paint graffiti littering has been applied, clean-up is where GraffitiTidy saves valuable time, expense and effort with easy graffiti removal.Download GraffitiTidy flyer here

Metal ShieldA metal-finish film renewing defaced metal surfacesMetal Shield is a grain-finish stainless-steel look film which provides a perfect 'veneer' to renew damaged stainless steel surfaces - or to give other flat surfaces a sleek stainless steel look. No need to repair prior scratched surfaces, Metal Shield can be installed over scratches bringing the surface back to as-new.

Mirror ShieldA mirror-finish film renewing defaced mirror surfacesMirror Shield is a reflective full mirror film which can effectively renew defaced mirrored surfaces - or upgrade other flat surfaces to have a mirror finish.No need to repair prior scratched mirrors, Mirror Shield can be installed over scratched glass to bring the surface back to as-new.Download Metal and Mirror Shield flyer here

Mirror ShieldA mirror-finish film renewing defaced mirror surfacesMirror Shield is a reflective full mirror film which can effectively renew defaced mirrored surfaces - or upgrade other flat surfaces to have a mirror finish.No need to repair prior scratched mirrors, Mirror Shield can be installed over scratched glass to bring the surface back to as-new.Download Metal and Mirror Shield flyer here

For more information please contact ross EathorneThis email address is being protected from spambots. You need JavaScript enabled to view it.Ph: 09 441 0040

Whether it’s apples from New Zealand or bananas from Ecuador, produce often travels great distances to get to the consumer and loss due to spoilage or other problems along the supply chain is costly and wasteful. But Swiss scientists have come up with a new sensor that could help solve this issue.

The temperature sensing device created by Empa Swiss Federal Laboratories for Materials Science and Technology looks and acts like a piece of fruit, down to its shape, size, surface texture, color, and internal composition. The self-powered wireless electronic sensor is surrounded by a solid shell made of polystyrene (a type of plastic), water, and carbohydrates that simulate the fruit’s flesh, according to Thijs Defraeye, a scientist at Empa who is leading the project. Traditional sensors used for this application usually only measure the air temperature in the freight container. To accurately gauge how produce is holding up, though, you need to know the fruit’s core temperature, as a warm inner can lead to spoilage.

The device can be tailor-made for the particular type of fruit, even down to a specific cultivar, like a Braeburn apple or a Kent mango, and it can be packed directly with the fresh produce while in storage or during shipping, says Defraeye. Once the shipment arrives at its destination, the data—things like what the fruits’ core temperature was over time—can be quickly analyzed to determine if there were any problems during the trip.

A fruit spy among mangoes. Empa

In the U.S., an average of 12 percent of fresh fruits and vegetables are lost before making it to the consumer. According to the United Nations’ Food and Agriculture Organization, globally about 1.4 billion tons of food—a value of more than $1 trillion—are lost or wasted each year, about 30 percent of which happens post-harvest (that includes storage and shipping).

Defraeye believes there are a variety of different applications for the sensor all along the supply chain—from greenhouses and orchards, to cold storage and ripening facilities, to the transportation sector—by exporters, importers, wholesalers, and retailers alike.

“They will be able to better pinpoint the location and reason for unexpected quality loss, which is essential for quality claims,” Defraeye tells Modern Farmer in an email.

Initial field tests on the sensors are under way and the researchers are now looking for potential industrial partners to manufacture the devices, which they believe would cost less than $50 per unit.

| A ModernFarmer release || April 18, 2017 |||

Taby, Sweden – Successfully solving the problems of using vacuum technology to convey the delicacies of the food industry, such as nuts, seeds, beans, candy, as well as nutraceutical tablets and capsules, Piab’s piFLOW®t conveyor is dedicated to the gentle handling of delicate ingredients and products. Promising to revolutionize the automated handling of fragile goods, the piFLOW®t features innovative and groundbreaking new technology (patent pending).

“A controlled low speed, guided entry into the conveyor, and the elimination of all sharp edges are the keys to our success, ensuring that products are handled with great care in our conveyors. There will be no more chipped candy in plants using piFLOW®t,” states Jarno Tahvanainen, Vice President of Piab’s Material Handling division.

Suitable for transporting up to four million items per hour, the piFLOW®t conveyor can be used to transport any fragile goods within a processing plant. For the food industry this enables the safe handling of, for instance, coated sweets, candy, roasted coffee beans, whole nuts, and nutraceutical tablets.

Eliminating the use of inadequate standard equipment and alternative, often back-breaking, manual procedures, piFLOW®t will safely transfer ingredients and products between the various processing units, such as tablet presses, coating drums, and packaging lines, avoiding all risks of damage.

At the core of piFLOW®t is the proprietary piGENTLE™ an innovative technology (patent pending) that maintains a gentle flow by regulating the feed pressure of the pump, ensuring that fragile ingredients or products are handled as delicately as possible. piFLOW®t is an extension to Piab’s popular and high quality range of piFLOW® conveyors for powder and bulk materials, and is specially developed to meet the stringent demands regarding operational safety and hygiene within the food (piFLOW®f), pharmaceutical (piFLOW®p), and chemical (piFLOW®i) industries.

About Piab

Established in 1951, Piab designs innovative vacuum solutions that improve the energy-efficiency, productivity, and working environments of vacuum users around the world. As a reliable partner to many of the world's largest manufacturers, Piab develops and manufactures a complete line of vacuum pumps, vacuum accessories, vacuum conveyors and suction cups for a variety of automated material handling and factory automation processes. Piab utilizes COAX®, a completely new dimension in vacuum technology, in many of its original products and solutions. COAX® cartridges are smaller, more energy efficient and more reliable than conventional ejectors, and can be integrated directly into machinery. This allows for the design of a flexible, modular vacuum system. In 2016, Piab completed two strategically important acquisitions, Kenos and Vaculex. Piab is a worldwide organization with subsidiaries and distributors in almost 70 countries. Its headquarters are in Sweden.

| An Ins release for Piab who are represented in New Zealand \\ April 19, 2017 |||

Mountains of slag all over the world are a Kiwi company's idea of great riches.

The waste from mines is dumped into mounds so big that they can generate their own weather patterns -- but New Zealand company Avertana says they can each be worth half a billion dollars.

Avertana is a start-up company that has received a kickstart from a new fund set up by The Icehouse innovation hub and its investors ICE Angels.

The "Tuhua" fund has raised $10 million dollars to target 25 Kiwi start-up companies.

ICE Angels CEO Robbie Paul says the idea is to be a game changer.

Continue to read the full article on Newshub || April 18, 2017 |||

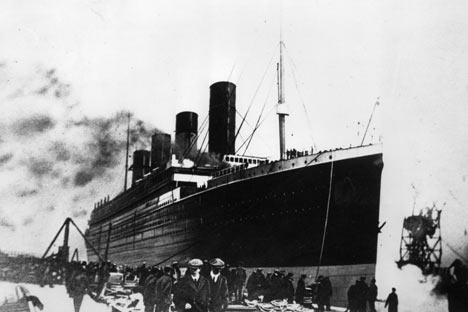

Reinforces New Zealand connections with doomed Atlantic Liner

New Zealand’s connection to the world’s most famous shipwreck the Titanic has become reinforced with the entry by Ocean Gate into the passenger tour business starting next year with scheduled dive tours to the wreck.

Ocean Gate is organised by Stockton Rush (pictured above) who is part of the family of the late Stockton Rush 11 who invented the high end terrestrial tourist business in New Zealand.

United States oilman Stockton Rush 11 developed Takaro Lodge in the South Island southern lakes district as a conservation and tourist centre for the rich.

The problem for the Lodge was that Mr Rush’s development coincided with the Labour government of Prime Ministers Norman Kirk and Wallace Rowling.

At this time the Labour government was anxious to be seen to be returning to its working class roots.

The publicity surrounding Takaro Lodge and especially its bathroom fittings which were said to be gold plated, along with the moneyed celebrities who stayed there meant that the Lodge became a target for government-inspired obstacles.

The current Stockton Rush is similarly in the premium tourist business, though this time of an undersea nature, and based in the United States.

Round dive costs have been calculated on an inflation adjusted formula relating to a first class trans-Atlantic berth on the Titanic itself (pictured below), this being in the region of NZ$150,000.

A qualified aerospace engineer and commercial pilot, Mr Rush is supervising the construction of his passenger dive craft known as Cyclops 2.

The Rush family’s tourist-based connection with New Zealand and the Titanic supplements the better known one of film magnate James Cameron and New Zealand.

It was Mr Cameron’s film, coincidentally financed by Rupert Murdoch, a continuing New Zealand omnipresence, that re-ignited the curiosity about the disaster and its causes and effects.

Subsequently New Zealand relatives have been discovered of Frederick Fleet the crows nest look out who first sounded the alarm about the imminence of the iceberg.

Mr Fleet later testified at the court of inquiry that the absence of any binoculars at his post meant that his warning came too late.

Meanwhile the Stockton Rush of Takaro Lodge fame an imposing-looking man who resembled the actor James Garner died at the age of 69 in 2000.

Mr Cameron with his numerous projects with New Zealander Peter Jackson resides in the Wairarapa Valley in which he has established a health foods grocery.

Lookout Frederick Fleet died in 1965.

| From the MSCNewsWire reporters' desk || Tuesday 18 April 2017 |||

Scientists have used some surprising and ingenious methods to get Greenshell™ mussels to breed in captivity and their efforts could soon be worth $200 million a year to the New Zealand economy.

Warm baths and vibrating devices are just two of the clever tricks New Zealand scientists have employed to get the famous (and somewhat shy) Greenshell™ mussels to breed on cue. The first crop from the SPATNZ hatchery is now ready to harvest and to eat, after years of investigative work in Nelson, New Zealand.

Scientist and SPATNZ boss, Rodney Roberts says it’s taken quite a bit of experimenting to get the mussels to give up their secrets.

“Normally these mussels breed in the wild and we wait for their babies, known as spat, to wash up on beaches attached to seaweed or land on catch ropes. That made life difficult for New Zealand mussel farmers, who had to cross their fingers and hope they would have enough spat for their farms from year to year.”

“We had to work pretty hard to figure out how to get the Greenshell™ mussels to breed reliably in our hatchery. We experimented with lighting, different bath temperatures and sounds and we finally settled on a combination of light, temperature and small vibrations that seems to really get the mussels going, encouraging them to produce maximum quantities of sperm and eggs.”

Rodney says the process might sound funny, but it has yielded seriously good results.

“We are now able to produce billions of mussel eggs each month and the great news is that these are growing into strong, faster growing and more consistent mussels.”

Mussel farmers agree. Bruce Hearn, who farms in the Marlborough Sounds and is also the Chairman of Aquaculture New Zealand says he’s incredibly excited about what it means for the industry.

“There are a lot of aspects to wild spat, it differs in quantity and quality, you never know when it is coming and when you can get it so there is no certainty. One of the advantages of hatchery spat is that we will know when we are getting it and we can plan for it. That will make a huge difference. It may be hard to appreciate just how much difference it will make, but that is a huge advantage on its own.”Gary Hooper the CEO of Aquaculture New Zealand agrees.

Hatchery spat is a game changer for our industry, it opens up all sorts of opportunities around selective breeding and product development in high value areas like nutraceuticals and superfoods. New Zealand mussels are already world famous but the hatchery unlocks a new level of innovation to take our industry to another level.”

The SPATNZ hatchery and the science behind it is the result of a collaboration between the Ministry for Primary Industries (MPI) and New Zealand’s oldest and biggest seafood company, Sanford, through the Primary Growth Partnership.

Sanford CEO, Volker Kuntzsch, who is a scientist himself (he has a Masters in Zoology), says he’s delighted to see the innovations at SPATNZ paying off.

“It’s always very satisfying when scientists can say that they’ve done it – they’ve confronted a problem head on in a smart way and they’ve solved it. Sanford is delighted that our mussel farmers will get real and significant benefits from SPATNZ’s hard work.”

Sanford and MPI are each investing $13 million into this PGP programme over its lifetime. Sanford and its contract growers will initially benefit from the research and technology but a requirement of this Primary Growth Partnership programme is that in time the technology will be shared with everyone in the industry.

MPI’s Director Investment Programmes Justine Gilliland says MPI is excited by the progress of the SPATNZ PGP programme and its prospects.

“The key things that we think are amazing opportunities for the programme are around not only the product in its raw form, those beautiful Greenshell™ mussels that we all love to eat, but also the opportunity for example, with nutraceutical products.“One of the requirements of PGP programmes is that, at the end of the day, the knowledge is disseminated more widely to the industry. We are really excited about the opportunity that the SPATNZ programme presents for the rest of the industry in New Zealand.”

Dan McCall, SPATNZ Operations Manager, says the whole programme is paying off, both in the hatchery and on the plate.

“It's really exciting. It’s a team effort and there have been many people over the years who have been involved, and now it is a reality. It’s great! We have already tasted a sample. We cooked some up for lunch the other day and yeah, we know they are good, we know they are delicious.”SPATNZ hatchery mussels are at harvest size now in the Marlborough Sounds and close to 500 tonnes of them will be harvested over the coming months.

Background

• The SPATNZ hatchery opened in 2015 in Nelson New Zealand and hatchery spat are currently growing on mussel farms in Pelorus Sound in Marlborough• 17 people are employed by SPATNZ at present• Greenshell™ mussels is the trademarked trading name for New Zealand green lipped mussels and sales of them in 2016 were worth around $350m• Greenshell™ mussels have anti-inflammatory properties and other characteristics that make them suitable for nutraceuticals• Aquaculture generally is worth around $530m to New Zealand annually and the industry wants to grow to be a billion dollar sector by 2025• When the programme reaches the end of its second stage, SPATnz expects to have developed hatchery methods capable of producing spat for around 30 thousand tonnes a year of adult mussels. Last year the industry produced a total of just over 80 thousand tonnes of Greenshell™ mussels• Mussels can swim. When they are in the larval stage they spend three weeks swimming around looking for a place to land, settle and grow.

| A SPATNZ release || April 10, 2017 |||

Palace of the Alhambra, Spain

By: Charles Nathaniel Worsley (1862-1923)

From the collection of Sir Heaton Rhodes

Oil on canvas - 118cm x 162cm

Valued $12,000 - $18,000

Offers invited over $9,000

Contact: Henry Newrick – (+64 ) 27 471 2242

Mount Egmont with Lake

By: John Philemon Backhouse (1845-1908)

Oil on Sea Shell - 13cm x 14cm

Valued $2,000-$3,000

Offers invited over $1,500

Contact: Henry Newrick – (+64 ) 27 471 2242