The UK and Brexit then the US and Trumplections - what is happening in the political arena? So will the coming months see a change inhow the election message is delivered to the voters in New Zealand for the 2017 elections?

Is MMP strong enough to weed out the Trumps of this world?

Of course time will duly deliver the answers but meanwhile ahead is an interesting time of rhetoric, promiseswrapped in appealing packaging, the ridiculous, the practical and the preposterous, its all part of the game hopefullythe rules will see the country end up with positive governance in place helping to improve productivity and the lifestyle of all New Zealanders.

Here on To The Beehive we will run as many of the release from across all the competitors. No starters gun, no umpire, linesme or third referee for that matter, just as it comes.

Releases can be sent to:- This email address is being protected from spambots. You need JavaScript enabled to view it.

The annual re-weighting of the Trade-Weighted Index (TWI) takes effect on Wednesday 16 November 2016.

The TWI is a measure of the value of the New Zealand dollar relative to the currencies of New Zealand’s major trading partners. There are 17 currencies included in the TWI and each currency is weighted using the country’s bilateral trade with New Zealand. The TWI weights for the next 12 months can be viewed here

Düsseldorf, Germany – Terex Port Solutions (TPS), the pioneer and technological pacesetter in terminal automation, starts a new chapter for operators of container terminals with Terex® diesel-electric straddle carriers. For the first time, TPS is automating a straddle carrier fleet for Ports of Auckland Ltd. (POAL) from New Zealand. By mid-2019, TPS will supply a total of 27 new, fully automated N SC 644 E (1-over-3) machines to work in the container stackyard and to serve trucks. At the same time, 21 existing manual straddle carriers are being upgraded so that they can work hand in hand with the 27 fully automated machines. In addition to the supply and upgrade of the vehicles, the order also includes all sub-systems and software systems required for operation. Before POAL placed the order, TPS verified the feasibility and safety of the concept in a detailed study. POAL is pursuing a double strategy: improved stacking capacity and high productivity

POAL currently operates a fleet of Terex N SC 634 E (1-over-2) diesel-electric straddle carriers and is pursuing a two-part strategy that includes the automation initiative and a step towards higher stacking capability which will deliver a medium-term increase in capacity from today’s 900,000 TEU to 1.6 to 1.7 million TEU. Tony Gibson, CEO Ports of Auckland Ltd.: “Due to community concerns, we cannot increase capacity at our container terminal through reclamation, so the only way is up. In future, we will use 1-over-3 straddle carriers in the container stackyard to

increase capacity. Automated straddle carriers also offer a number of other benefits: They are inherently safer, as there is no human on board; they deliver a positive environmental impact as they will consume up to 10% less fuel and produce lower emissions; they will be quieter and need less light on the terminal, reducing both noise and light pollution. Overall, automation offers us safety, environmental, community and capacity benefits.” In future, POAL will only use the existing 1-over-2 machines for horizontal container transport between ship-to-shore cranes and the storage area, which will help POAL maintain its currently high levels of productivity.

Comprehensive: all sub-systems and software systems also from TPS

Steve Filipov, President Terex Cranes and Material Handling & Port Solutions, is delighted to achieve another milestone in automation: “Automation will enable increased capacity and safe, efficient operations for terminals that organize container transport and storage with straddle carriers. We are pleased that this comprehensive project gives us the opportunity to help an ambitious terminal operator such as POAL with its long-term development objectives.” As a supplier of integrated systems, TPS is also responsible for all sub-systems required to operate the partly modified, partly newly assembled fleet. In addition to the TEAMS fleet management system, these sub-systems include the Navimatic® navigation system based on a terrestrial system and its corresponding antennae to determine the position of the vehicles. TEAMS and Navimatic, successfully implemented on several occasions by TPS in major terminals for automated operations in the past, have now been adapted to the specific requirements of straddle carriers to control the automated operations in Auckland. TPS will supply the interchange and fence control system, safety-relevant vehicle control systems and various sensor systems that will enable smooth interplay between the automated vehicles and manual straddle carriers, as well as other functions operated by staff in the terminal.

TPS well-equipped thanks to extensive test program

With its latest innovation, TPS is fulfilling the wish of many terminal operators to automate straddle carrier terminals. In addition, many terminals that currently use manual 1-over-1 sprinter carriers between ship-to-shore cranes and container stackyards would like to convert to automated machines in the future. Klaus Peter Hoffmann, Vice President & Managing Director TPS: “Against the backdrop of increasing demand, several years ago we started a comprehensive research and development program, in the course of which we created automation technology for both Terex straddle carriers and Terex sprinter carriers. We tested this over many months on prototypes at our testing grounds near the TPS competence center for straddle carriers in Würzburg, Germany, where we looked at design and operating principles, the control system, and the features of the positioning system. Our technology is now ready for market and has impressed POAL.”

Pioneer in automation: cutting edge with an integrated approach

TPS has been at the cutting edge of automation technology for port handling for a quarter of a century, and gradually expanded its range of products and services after the introduction of the first Terex® Gottwald automated guided vehicles (AGV), which were ready for series production in 1992. Initially the software required for operating AGV’s was supplied by the terminal operator or by third parties. Thanks to its growing experience in this area, TPS was able to take over development of navigation and management software. In addition to several AGV product lines, today’s TPS portfolio includes automated stacking cranes (ASC) for the container stackyard including the required software.

Thanks to the simultaneous delivery of the sub-systems required for automated transport and automated storage of containers, TPS is now a supplier of complete systems who can draw on a wealth of experience. And long before the first cut of the spade, TPS also provides support for its customers with the consultation services of its software brands, which include the simulation and emulation of terminal processes. Hoffmann: “Our wealth of experience, in addition to our unique range of automation products, makes us the natural partner for innovative solutions, as has now been demonstrated by the first order for fully automated straddle carriers from New Zealand. With this reference installation, we believe that we are perfectly positioned to convert more existing manual terminals into semi or fully automated terminals and to equip green field port facilities.”

Düsseldorf, Germany – Terex Port Solutions (TPS), the pioneer and technological pacesetter in terminal automation, starts a new chapter for operators of container terminals with Terex® diesel-electric straddle carriers. For the first time, TPS is automating a straddle carrier fleet for Ports of Auckland Ltd. (POAL) from New Zealand. By mid-2019, TPS will supply a total of 27 new, fully automated N SC 644 E (1-over-3) machines to work in the container stackyard and to serve trucks. At the same time, 21 existing manual straddle carriers are being upgraded so that they can work hand in hand with the 27 fully automated machines. In addition to the supply and upgrade of the vehicles, the order also includes all sub-systems and software systems required for operation. Before POAL placed the order, TPS verified the feasibility and safety of the concept in a detailed study. POAL is pursuing a double strategy: improved stacking capacity and high productivity

POAL currently operates a fleet of Terex N SC 634 E (1-over-2) diesel-electric straddle carriers and is pursuing a two-part strategy that includes the automation initiative and a step towards higher stacking capability which will deliver a medium-term increase in capacity from today’s 900,000 TEU to 1.6 to 1.7 million TEU. Tony Gibson, CEO Ports of Auckland Ltd.: “Due to community concerns, we cannot increase capacity at our container terminal through reclamation, so the only way is up. In future, we will use 1-over-3 straddle carriers in the container stackyard to

increase capacity. Automated straddle carriers also offer a number of other benefits: They are inherently safer, as there is no human on board; they deliver a positive environmental impact as they will consume up to 10% less fuel and produce lower emissions; they will be quieter and need less light on the terminal, reducing both noise and light pollution. Overall, automation offers us safety, environmental, community and capacity benefits.” In future, POAL will only use the existing 1-over-2 machines for horizontal container transport between ship-to-shore cranes and the storage area, which will help POAL maintain its currently high levels of productivity.

Comprehensive: all sub-systems and software systems also from TPS

Steve Filipov, President Terex Cranes and Material Handling & Port Solutions, is delighted to achieve another milestone in automation: “Automation will enable increased capacity and safe, efficient operations for terminals that organize container transport and storage with straddle carriers. We are pleased that this comprehensive project gives us the opportunity to help an ambitious terminal operator such as POAL with its long-term development objectives.” As a supplier of integrated systems, TPS is also responsible for all sub-systems required to operate the partly modified, partly newly assembled fleet. In addition to the TEAMS fleet management system, these sub-systems include the Navimatic® navigation system based on a terrestrial system and its corresponding antennae to determine the position of the vehicles. TEAMS and Navimatic, successfully implemented on several occasions by TPS in major terminals for automated operations in the past, have now been adapted to the specific requirements of straddle carriers to control the automated operations in Auckland. TPS will supply the interchange and fence control system, safety-relevant vehicle control systems and various sensor systems that will enable smooth interplay between the automated vehicles and manual straddle carriers, as well as other functions operated by staff in the terminal.

TPS well-equipped thanks to extensive test program

With its latest innovation, TPS is fulfilling the wish of many terminal operators to automate straddle carrier terminals. In addition, many terminals that currently use manual 1-over-1 sprinter carriers between ship-to-shore cranes and container stackyards would like to convert to automated machines in the future. Klaus Peter Hoffmann, Vice President & Managing Director TPS: “Against the backdrop of increasing demand, several years ago we started a comprehensive research and development program, in the course of which we created automation technology for both Terex straddle carriers and Terex sprinter carriers. We tested this over many months on prototypes at our testing grounds near the TPS competence center for straddle carriers in Würzburg, Germany, where we looked at design and operating principles, the control system, and the features of the positioning system. Our technology is now ready for market and has impressed POAL.”

Pioneer in automation: cutting edge with an integrated approach

TPS has been at the cutting edge of automation technology for port handling for a quarter of a century, and gradually expanded its range of products and services after the introduction of the first Terex® Gottwald automated guided vehicles (AGV), which were ready for series production in 1992. Initially the software required for operating AGV’s was supplied by the terminal operator or by third parties. Thanks to its growing experience in this area, TPS was able to take over development of navigation and management software. In addition to several AGV product lines, today’s TPS portfolio includes automated stacking cranes (ASC) for the container stackyard including the required software.

Thanks to the simultaneous delivery of the sub-systems required for automated transport and automated storage of containers, TPS is now a supplier of complete systems who can draw on a wealth of experience. And long before the first cut of the spade, TPS also provides support for its customers with the consultation services of its software brands, which include the simulation and emulation of terminal processes. Hoffmann: “Our wealth of experience, in addition to our unique range of automation products, makes us the natural partner for innovative solutions, as has now been demonstrated by the first order for fully automated straddle carriers from New Zealand. With this reference installation, we believe that we are perfectly positioned to convert more existing manual terminals into semi or fully automated terminals and to equip green field port facilities.”

Forge platform surpasses 4,000 applications, demonstrating high demand for connected design and engineering experiences

Las Vegas--(BBusiness Wire) November 15, 2016 01:00 PM Eastern Standard Time-- At Autodesk University, Autodesk, Inc. (Nasdaq:ADSK) announced that developers and customers of all sizes are adopting its Forge platform to build and deploy apps and services for making the world around us. The company also introduced new AR/VR capabilities to drive immersive real-time industry experiences and shared its plans to use Forge as its common data environment and engine for simplifying its own product offerings.

Since announced at Autodesk University 2015, Autodesk Forge has expanded to include more robust integrations to manufacturing and construction enterprise systems to streamline collaboration, integrate with manufacturing and BIM workflows and make it easier to get things made. The more than 4,000 apps and services created on Forge span a variety of business needs ranging from part inspection to sub-sea surveying, from managing mines with drones to turning cost estimation into a competitive advantage.

Autodesk has aggressively broadened the Forge platform and ecosystem in the past twelve months. The most recent platform enhancements and future plans include:

“Autodesk relies on Forge as the foundation for its own cloud services like Fusion 360 and BIM 360, and we want both developers and our end customers to benefit from creating lightweight applications that fit their business needs,” said Amar Hanspal, SVP products at Autodesk. “Forge is empowering companies to build and deliver all sorts of industry applications, and we are thrilled to see the range of connected experiences created with our platform in just one year.”

Forging the Future Together

Autodesk invests in and partners with companies developing innovative solutions and services on the Forge Platform. JE Dunn, MakeTime and Seebo are a few of the companies using Forge for building apps and services.

“We’re very excited about the integration between Autodesk Forge and Seebo, which will provide Autodesk customers with access to some of the most cutting edge IoT development tools available. The joint platform allows manufacturers to tap into the world of IoT efficiently and cost effectively,” said Lior Akavia, Co-Founder and CEO of Seebo.

Forge for Autodesk

Cloud-native and always connected, Forge is the platform in which Autodesk is building three industry specific experiences that span design, make and use for each of our major industries. Each offering is built on a common data environment with a set of lightweight applications and experiences that work across multiple platforms such and personas. Whether used internally by Autodesk for development and simplification or externally by companies to deliver and deploy apps and services, the Forge platform is the backbone to make anything. To learn more about Forge, visit https://forge.autodesk.com/.

In new 270-degree view auditorium and visitor’s centre

Fonterra in New Zealand is a significant organisation. In addition to their leading consumer brands and foodservice business the company operates more than 30 manufacturing sites across the country and processes about 16 billion litres of the country’s milk each year. With this in mind when Fonterra decided to centralise all of their staff into one new Auckland-based HQ two very specific audio visual requirements needed to be met and for those they turned to Epson and their EB-G6970WU multi-media projectors.

Design Engineering Manager for Automation Associates (AA) - the systems integrator on the project - Rupert Brown explained, “Previously Fonterra’s 1500 employees were spread over three separate buildings. Earlier this year the company made the decision to go with a new, more efficient, activity-based working model and centralise all of their staff into one main building. Part of this building housed a new auditorium and a new visitor’s centre and both areas had very specific AV requirements.”

The auditorium project was particularly ambitious as it was to be equipped to a high enough standard that Fonterra would no longer need to hire external venues for presentations.

As part of AA’s response to Fonterra’s brief the company’s design and installation included edge-blending the EB-G6970WU projectors across the entire background being projected upon within the auditorium.

Brown continued, “Fonterra wanted a wow factor in the auditorium so we came up with a design that integrated thirteen Epson EB-G6970WU projectors which seamlessly edge blended to give a 270-degree projection onto custom-designed motorised screens. This is incredibly impressive as it means Fonterra can now dynamically change the screen and edge blending as the room configuration changes.”

For the training, seminars, group workshops, host events and press conferences held in the Fonterra auditorium the new 270-degree projection solution raised a bar in presentation standard to a level never seen before.

To achieve this unique dynamic edge-blending 270-degree projection solution AA used the award-winning Coolux Pandoras Box media and show control system to handle the edge blending, whilst simultaneously communicating with the projectors’ via the output fed into a custom-created digital media frame.

AA also configured the auditorium so the screens could be divided down the centre which gave Fonterra the option of two separate 270-degree rooms or a larger combined 270-degree projection system.

According to Brown there were several reasons the EB-G6970WU projectors were chosen for this project, many of which revolved around quality of image, reliability and functionality.

He continued, “We chose the EB-G6970WU projectors as they have a good short throw for minimum shadow when a viewer approaches the screen and they easily enabled us to cover the 45 meters of screen we needed at an affordable price. The lens on the EB-G6970WU was also a big part of why it was selected as it allowed us to reduce the number of projectors required while still being short enough that shadows aren’t cast until close to the screen. Finally having on-board HDBaseT was a big win as it reduced the required hardware and cabling to connect the projectors.”

The visitor’s experience centre presented a different challenge according to Brown who explained, “In the visitor’s experience centre Fonterra wanted to project pre-recorded exhibits and pre-made videos with ultra-sonic sensors built into the ceiling so the projection would start as the visitor approached. What was needed here was a top quality, highly reliable and very easily integrated projector. So, based on the success of the auditorium installation, the decision was made to again go with multiple Epson EB-G6970WU projectors, all of which work perfectly with the sensors and perform brilliantly.”

For more information on the Epson EB-G6970WU projectors go to: http://www.epson.co.nz/products/projector/EB-G6970WUNL.asp

15 Nov 2016 --- Bolstered by rapid consumption growth and increasing customer needs in the Asia-Pacific region, Tetra Pak have announced their US$110 million investment in a state-of-the-art regional manufacturing facility near Ho Chi Minh City, Vietnam, to serve customers across the region.

The move is prompted by increasing consumption volumes, with the 2016 total packed liquid dairy and fruit-based beverages intake at 70 billion litres across ASEAN, South Asia, Japan, Korea, Australia and New Zealand. Additionally, over the next three years, these markets are likely to grow at a healthy 5.6% per annum, with products packed in Tetra Pak cartons projected to grow at a much faster rate as compared to other packaging formats such as glass bottles and cans.

“Tetra Pak has been present in the region for decades, with our first factory set up in Gotemba, Japan in 1971,” said Michael Zacka, Regional Vice President, Tetra Pak South Asia, East Asia and Oceania. “Over the years, we have seen substantial growth of our products, driven by a wide portfolio and a number of innovations that we have introduced in the market. Hence our investment in a new plant, which will be our fourth Packaging Material factory in the region, providing us expansive coverage and scale. Continue to Full article

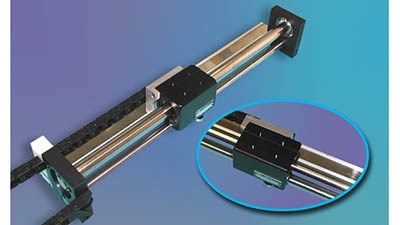

Aston Pennsylvania – Amacoil-Uhing Model RS drive nuts provide smooth backlash-free linear motion in machine design. Unlike a screw, the RS drive nut runs on a smooth shaft. This eliminates the potential for debris to become trapped in threads which could then clog or jam. If material does fall onto the shaft, it is easily removed by wiping the shaft with a clean cloth. Should an object somehow become caught between the nut and the shaft bearing end support, the drive simply slips until the operator can remove the obstruction. Slipping, as opposed to the churning and grinding associated with screw-based systems, prevents damage to the nut and other components in the linear motion system which, in turn, reduces downtime for repairs and enables more consistent production rates.

Aston Pennsylvania – Amacoil-Uhing Model RS drive nuts provide smooth backlash-free linear motion in machine design. Unlike a screw, the RS drive nut runs on a smooth shaft. This eliminates the potential for debris to become trapped in threads which could then clog or jam. If material does fall onto the shaft, it is easily removed by wiping the shaft with a clean cloth. Should an object somehow become caught between the nut and the shaft bearing end support, the drive simply slips until the operator can remove the obstruction. Slipping, as opposed to the churning and grinding associated with screw-based systems, prevents damage to the nut and other components in the linear motion system which, in turn, reduces downtime for repairs and enables more consistent production rates.

Designers of automated machinery requiring a linear motion component will find RS drive nuts meet requirements for a variety of indexing and reciprocating linear motion applications. When integrated with sensing devices such as a linear scale, RS drive nuts provide high accuracy, back-lash free linear motion in material handling machines, winding equipment, test and measurement devices, metrology machinery, packaging machines, and other converting and finishing equipment. Continue to read full article

Dutch coffee giant has Jacobs Douwe Egberts (JDE) has received Overseas Investment Office approval for the acquisition of BrewGroup NZ (formerly Bell Tea & Coffee Co).

The price is undisclosed and the approval comes with conditions that the company explore opportunities to increase exports and put some of its Kiwi brands on the global stage.

JDE Australia and New Zealand managing director David Ansell says the acquisition will be completed by December 1. The two companies will continue to operate as separate operating units for the next two months with integration to begin in February 2017. Continue to read article on NBR

Science and Innovation Minister Steven Joyce has today announced that the Centre for Space Science Technology (CSST) has been selected to become New Zealand’s second Regional Research Institute.

“The Centre for Space Science Technology, which will be based in Alexandra, Central Otago, will undertake research to explore the use of space-based measurements and satellite imagery unique to New Zealand to meet the specific needs of our regional industries,” Mr Joyce says.

“It will establish an international satellite data exchange and collaborate with leading researchers and businesses, both here and abroad, to design, build and launch New Zealand’s first fleet of cube satellites.”

The Government will provide funding of up to $14.7 million over four years for the new institute with additional funding from industry, and it will operate as a private, independently governed organisation.

“In its proposal to establish a Regional Research Institute, CSST presented a strong business case that will support the development and growth of New Zealand’s space economy by filling critical gaps in the collection and processing of New Zealand’s satellite data,” says Mr Joyce.

“A standout aspect of the proposal was that CSST will also have research hubs in Dunedin, Canterbury and Taranaki, further encouraging R&D and innovation in regional New Zealand – a key objective of the Regional Research Institute initiative.”

CSST is the second successful proposal under the initiative following the launch of the New Zealand Research Institute of Viticulture and Oenology (NZRIVO), based in Marlborough, in October.

A third shortlisted proposal by Earth+Vantage, based in Southland, which proposed undertaking research using real time satellite and ground-based data to lift primary industry productivity was unsuccessful in its application but will have the option to put forward a proposal for the second round of funding. An additional sum of $2.3 million has also been set aside for technical collaboration between CSST and Earth+Vantage if this proves possible.

Minister Joyce today also opened a second round of funding for the Regional Research Institutes initiative.

Regional Research Institutes were announced in Budget 2015. In Budget 2016, the Government set aside $40 million of additional funds to support the initiative, bringing the total funding in contingency to $65 million over four years.

Proposals are invited from groups of businesses, researchers and private investors who are seeking to collaborate to establish regional institutes that will deliver commercially focused and industry-relevant research to their region and New Zealand as a whole.

“During the initial funding round, a number of credible and exciting proposals were received from all across New Zealand on a wide range of research and development interests,” says Mr Joyce.

“Our regional economies have different resources and strengths. These institutes will focus on scientific research relevant to a particular region, with a strong emphasis on the effective transfer of research into new technologies, new firms, and new products and services.”

It is expected that two or three additional institutes will be established over the next four to five years in areas outside Auckland, Wellington and Christchurch.

Proposals are due to MBIE by 27 January 2017. Shortlisted proposals will be invited to present to a panel of experts and, if selected, will develop business cases for consideration.

More information on the Regional Research Institutes initiative is available at http://www.mbie.govt.nz/info-services/sectors-industries/regions-cities/...

Palace of the Alhambra, Spain

By: Charles Nathaniel Worsley (1862-1923)

From the collection of Sir Heaton Rhodes

Oil on canvas - 118cm x 162cm

Valued $12,000 - $18,000

Offers invited over $9,000

Contact: Henry Newrick – (+64 ) 27 471 2242

Mount Egmont with Lake

By: John Philemon Backhouse (1845-1908)

Oil on Sea Shell - 13cm x 14cm

Valued $2,000-$3,000

Offers invited over $1,500

Contact: Henry Newrick – (+64 ) 27 471 2242