A total of 15,691 candidates appeared in the entry test for admission to the public sector engineering universities of . . .?

Dave (left) and Nate (right) Evans, cofounders of Fictiv, believe anyone with an internet connection should have access to production-grade manufacturing machines (image courtesy of Fictiv).

Dave and Nate Evans, cofounders of Fictiv, run what they describe as “a manufacturing platform” from a small office in San Francisco’s Civic Center. Walking inside, you come across whiteboards with scribbles and doodles, staffers squinting at Macs and PCs, and a friendly, fluffy golden retriever that belongs to an employee. What you don’t see are rows and rows of 3D printers and CNC (computer numeric controlled) machines cranking out parts.

How, then, does Fictiv deliver on its promise to produce your 3D printed parts in 24 hours and machined parts in three days? The answer rests with the way Fictiv harnesses its network of manufacturing partners.

Dave, a Stanford-trained mechanical engineer and one of the earliest employees of Ford’s Research Lab in Palo Alto, is Fictiv’s CEO. Nate, a designer, artist, and entrepreneur with a master’s degree in Chinese, is Fictiv’s Chief Experience Officer. (Nate’s title is abbreviated as CXO, thus the awkwardness of having two CEOs is averted.)

“Fictiv is the most efficient way for manufacturers and industrial designers to fabricate their parts,” said Nate. His vision is, “anyone with an internet connection should have access to the kind of production-grade machines Ford or Tesla would use.”

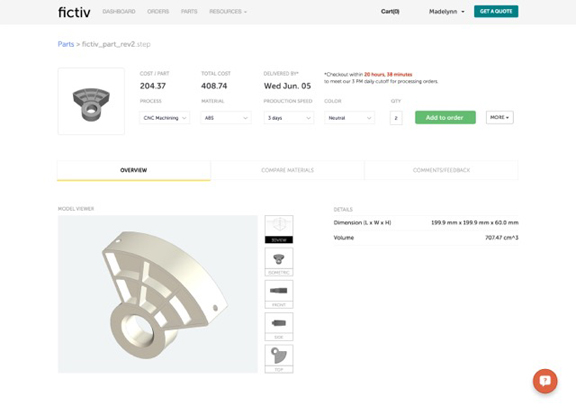

Fictiv built the software infrastructure to submit digital files, get quotes, and place orders. Users get a series of technology and material options relevant to the production method they’ve specified (for example, inexpensive PLA parts, strong ABS parts, or transparent parts in 3D printing).

Fictiv’s online ordering system automatically inspects the submitted part to ensure it can be made (image courtesy of Fictiv).

Fictiv’s online ordering system automatically inspects the submitted part to ensure it can be made (image courtesy of Fictiv).

A key component of Fictiv’s browser-based software is the automated design for manufacture (DFM) analysis. Dave explained, “When you upload a part, the software is looking at it to see if the part can be produced.”

If the geometry is flawed or unsuitable for machining, the customer gets instant feedback, with suggested remedies. In the preliminary estimate, the analysis is software-driven. But once the customer requests a full quote, a mechanical engineer on Fictiv’s staff inspects the file in person.

While some crowd-funded startups may have no qualms about uploading their concepts to a cloud-hosted software, many in traditional manufacturing, such as automotive and aerospace, still wrestle with the security concerns of the cloud. Dave said, “That’s why we sign a lot of NDAs,” but also pointed out the concerns may be disproportionate to the real risk.

“When you’re emailing your design to get quotes, you don’t know what happens to those file attachments,” he said. “With our system, only the vendor who’s going to produce the part will get to see the file — nobody else.”

The actual production is done by its manufacturing vendors, who are recruited, vetted, and brought on board with rigor and diligence. The vetting process takes two weeks, Dave revealed.

“Machine shops go through ebbs and flows,” Dave pointed out. “So we leverage the idle machines to produce parts on demand. We bundle a lot of orders from different customers and drive business to a vendor, so we have a lot of purchasing power.”

Currently, Fictiv targets startups, innovators, inventors, and designers who need parts produced in quantities of 500 or lower.

With the ability to produce low-volume parts at a reasonable cost, 3D printing empowers a whole new wave of makers, innovators, and inventors who would not otherwise be able to turn their ideas into reality. However, most 3D-printed parts do not have the same strength as machined metal parts. Metal parts are easy to produce in CNC, but the technology favors large volume production. The fact that Fictiv’s platform offers both choices for low or moderate volume is significant.

Stratasys, a 3D printing machine maker, offers on-demand manufacturing services through its Stratasys Direct Manufacturing division. Production options include PolyJet, stereolithography, laser sintering, and CNC machining.

Another on-demand additive manufacturing vendor, CloudDDM, gets its speed advantage by building its operations close to the UPS distribution center in Louisville, Kentucky. The company offers single-day turnaround for 3D-printed parts. Makers, inventors, and engineers may also turn to 3D Hubs, a site that lists 3D printing service providers by region, to produce their prototypes.

For small and midsize businesses that do not have onsite production facility, on-demand manufacturing service providers fill a critical need. They become the remote manufacturing arm, an extension of the in-house design team.

Her Majesty always committed to Commonwealth but Doctrinal UK commentators bamboozle naïve NZ counterparts

Three powerful figures are now ranged behind a restoration of the Commonwealth trade and emigration bloc centred on Canada, Australia, and New Zealand.They are Her Majesty the Queen, foreign secretary Boris Johnson, and international trade secretary Dr Liam Fox.

Her Majesty is known to favour a return of the active and operational Commonwealth era. The Queen is the head of the Commonwealth and has remained its consistently most ardent supporter.

Foolishly, what is left of the print media here, and which is in thrall to elements of the UK newspapers of the type that sends begging letters for donations to random New Zealanders, has been seriously misled.

This is because speeches written for Her Majesty, which she is obliged under the terms of the British Constitution to deliver word for word, had been naively taken by, for example, The Guardian, to indicate that the Queen had doubts personally about Brexit.

In the event it is the Queen’s privately uttered give-me-three-good-reasons that is now taken by the non-doctrinal dailies in the UK to have accurately reflected the royal view concerning membership of the EU.

Foreign secretary Boris Johnson’s support of the Canada-Australia-New Zealand bloc has been unreservedly-voiced during his previous job as mayor of London.

New trade secretary Dr Liam Fox who visited New Zealand while he was chairman of the Conservative Party made a point while he was here of talking to everyday New Zealanders in order to get his own views on attitudes.

Dr Fox was an un-reserved Brexiteer who made no effort to hedge what turned out to be a successful bet on his part. He campaigned on what he saw as the unsustainable level of immigration created by EU membership.

From the MSCNewsWire reporgters desk July 18, 2016This email address is being protected from spambots. You need JavaScript enabled to view it.

Sandvik Coromant will reveal for the first time at IMTS 2016 new connectivity-based solutions designed to help manufacturers optimize their machining and decision making process. The new solutions have been developed to improve every aspect of it, from design, production planning and through machining to post-process analysis and intelligence.

Digitalization within manufacturing is increasingly important for the digital manufacturing future success of machine shops the world over however; embarking on this transformational journey brings also challenges and complexities. To help manufacturers overcome them, Sandvik Coromant has devised digital solutions that support those looking to take steps towards a connected future.

“Sandvik Coromant has a long heritage of bringing new technology developments to the metal cutting industry, each of which is based on the values that our customers hold highest, such as greater productivity and profitability,” says Magnus Ekbäck, Vice President Business Development at Sandvik Coromant. “Connected software and hardware does the same thing but in a different way. At IMTS, visitors will discover how advancements such as data exchange and machining intelligence will improve efficiency and optimize production processes. New technologies open new possibilities and we are keen to share our knowledge and help customers take the lead in digital machining.”

The data collected at each step of the digital machining processes combined with Sandvik Coromant’s competence in interpreting and optimizing them will provide manufacturers with better insight about their machining environment and ultimately help them increase their overall profitability. For those wanting to discuss how best to benefit from digital advances such as connectivity, digital machining and big data, as well as the latest machining trends, leading experts from Sandvik Coromant will be available at IMTS 2016 to engage in discussion and address visitors’ specific inquiries. A wide selection of tools will also be on show at the exhibition, some of which will be taking part in live demonstrations.

IMTS 2016 takes place on 12-17 September at McCormick Place, Chicago, USA. Sandvik Coromant has two booths at the show, W-1500 (West Building) and NC-509 (North Building, Hall C).

Source: A Sandvic Coromant press release July 14,2016

“It is a normal part of any FTA,” points out Auckland Chamber of Commerce head Michael Barnett.

If a complaint has been made then there is a process both countries are required to go through. Both countries would be looking into it, said Mr Barnett.

He was commenting on a news report that China was threatening retaliatory measures against New Zealand over alleged dumping of cut-price steel on the New Zealand market.

For more information contact Michael Barnett, mobile: 0275 631 150.Michael Barnett, Chief Executive, Auckland Chamber of Commerce.

Trade Minister Todd McClay is traveling to Indonesia today to join the Prime Minister and a high-level business delegation for a two-day official visit.

“Indonesia is an important trade partner for New Zealand, and as our 11th largest export market offers significant trading opportunities.

“Our two-way trade currently sits at $1.6 billion, and we're keen to explore ways to meet the target set by the two countries last year to boost trade to $4 billion by 2024,” says Mr McClay.

“We will be looking to further broaden our trade connections, including through the Prime Minister’s meeting with Indonesian President Joko Widodo and my own meeting with Indonesian Trade Minister Thomas Lembong.”

Mr McClay spoke with Minster Lembong at last weekend’s G20 meeting in Shanghai and both ministers committed to further develop their government-to-government and business-to-business links.

"With a population of 255 million, Indonesia offers significant opportunity to New Zealand exporters and we will be looking to capitalise on the Prime Minister's visit to open doors for New Zealand companies," says Mr McClay.

While in Indonesia, Mr McClay will take part in business forums in Jakarta and Surabaya. The Jakarta business forum will focus on the benefits of regional economic integration, including between ASEAN and New Zealand. The Surabaya business forum will aim to promote New Zealand’s economic relationship with East Java, Indonesia’s second most populous province.

“I look forward to working alongside the New Zealand business delegation to showcase New Zealand’s commercial expertise in areas of priority for Indonesia, including renewable energy, food and beverage, aviation, education and tourism,” says Mr McClay.

Source: Minister of Trade Todd McClay July 17, 2016

World War I saw the first use of aircraft in large-scale conflicts and the battlefield has never been the same since. These early airplanes used rotary engines, in which the crankshaft remains stationary while the rest of engine rotates around it.

You won’t see many original WWI aircraft engines still in use today, but if you happen to visit a small machine shop in New Zealand, you can order a brand-new one. In addition to making parts for vintage aircraft and general machining services, Classic Aero Machining Service is building 1915 Gnome engines using modern manufacturing techniques. “Our idea was to produce original rotary engines which were safe, reliable and affordable,” said Tony Wytenburg, chief engineer and managing director of Classic Aero Machining Service. “I’ve been in business since 2004; I can’t say I enjoy everything about running a small business, but I do take great satisfaction from making parts. Being able to make a lot of parts which, when finished, is a running engine is one of the most satisfying things I’ve ever done.”

Pictured to the right is a a brand-new Gnome rotary engine courtesy of Classic Aero Machining Serivce.

Read the full article here by ENGINEERING.com who had the chance to get Wytenburg’s insights on this unique project - July 15, 2016

International packaging company Orora Limited has invested more than $25 million to support its growing New Zealand customer base and increase its manufacturing capabilities. The company has key manufacturing operations in Christchurch, Hastings and Auckland and has made significant investments at each site.

“The New Zealand market is core to Orora’s Australasian business growth strategy as is evidenced by our ongoing financial commitment to our Orora Kiwi Packaging operations,” Orora Limited CEO and Managing Director Nigel Garrard said.

“Our investment in a new state of the art Flexo Folder Gluer (FFG) - a complete box making solution that increases capacity, print capability and print quality - in our Christchurch facility, reinforces our strong business confidence in the New Zealand South Island as it rebuilds following the earthquakes that severely impacted the region,” Mr Garrard said.

Investment in Orora’s Hastings operations has helped to increase production capacity and reduce repetitive handling processes to meet future demand for the company’s valued kiwi fruit, meat and apple customers. Orora’s investment includes a new FFG, a Rotary die-cutter to increase the sites capacity, along with a new automation solution for its latest die-cutter. The company has also created 40 new jobs in the Hawkes Bay area as it continues to invest in regional business areas.

Orora has also recently approved further capital investment in its Auckland Operations for a new generation FFG, and a new materials handling system to add to its automation investment to reduce repetitive handling. This adds to its recent investment in a state of the art high quality printer to meet the current and future requirements of its valued customers in the region.

Orora is a leading supplier of packaging products. In New Zealand, Orora delivers fibre packaging through its corrugated packaging business, Orora Kiwi Packaging.

Source:

Modern bikes are lighter and more efficient than ever before, but their basic design is rooted in the past.

Cyclotron is trying to change that with a hubless carbon creation, complete with lighting fit for a sci-fi film. It's not just a different look for the sake of it, though, with Cyclotron saying its bike is versatile and smart enough to revolutionize what we expect from the humble two-wheeler.

In this article published recently on GizMag the story behind this futuristic design unfolds. There's a lot going on with the Cyclotron's frame, but we're going to start with the basic construction. The team behind the bike says the bike's space-grade carbon sandwich is wrapped around a lightweight core structure, allowing them to use fewer layers of carbon and less resin without impacting on the overall strength and rigidity.

The shape itself is faintly reminiscent of current time-trial bikes, albeit blockier, although the company is adamant it's been modeled on the aerodynamic form of ultralight gliders and stealth jets. Unlike your average stealth bomber, this frame can be customized with decals if you want.

Whether it's a two-wheeled Blackbird or not, there are a few other benefits to the frame design. While some manufacturers hide their cabling inside the frame, the derailleur and chain are usually exposed. That's not the case here, with the drivetrain fully enclosed and protected from the elements, although we're not sure how that setup will go when it comes time for the annual service suggested by the company.

Ditching the spokes and running with solid polymer airless tires might make for a unique design, but it also frees up some space where the spokes used to be. Cyclotron wants to use that space for cargo or children, making its bike more practical than it would otherwise be. At the moment, there are three accessories available for those utility slots, including shopping baskets and a clever snap-in child seat.

In keeping with the futuristic frame design, there's a futuristic powertrain available for this sci-fi bike. As well as more traditional 12- and 18-speed manual setups, there's a electronic sequential gearbox available. Shifting in less than 0.2 seconds, the gearbox works at standstill or under full load and can shift for itself. Electric gearbox-equipped bikes will weigh just 11.6 kg (25.57 lb), making them 100 g (3.5 oz) heavier than the manual 12-speed version, but 200 g (7 oz) lighter than the 18-speed manual.

Enough of the boring practical bits, what the story with those lights? When darkness falls, a sensor automatically activates the LED wheel halos and laser-lane display, in an attempt to make the rider easy to see on unlit streets in the dead of night. We'd say it works, too, with those Tron-style wheels being hard to miss. Power comes from an integrated lithium-ion battery good for eight hours that is charged by an inbuilt dynamo, although the battery can be charged from a wall socket as well.

Continue reading and view the video here

Modern bikes are lighter and more efficient than ever before, but their basic design is rooted in the past.

Cyclotron is trying to change that with a hubless carbon creation, complete with lighting fit for a sci-fi film. It's not just a different look for the sake of it, though, with Cyclotron saying its bike is versatile and smart enough to revolutionize what we expect from the humble two-wheeler.

In this article published recently on GizMag the story behind this futuristic design unfolds. There's a lot going on with the Cyclotron's frame, but we're going to start with the basic construction. The team behind the bike says the bike's space-grade carbon sandwich is wrapped around a lightweight core structure, allowing them to use fewer layers of carbon and less resin without impacting on the overall strength and rigidity.

The shape itself is faintly reminiscent of current time-trial bikes, albeit blockier, although the company is adamant it's been modeled on the aerodynamic form of ultralight gliders and stealth jets. Unlike your average stealth bomber, this frame can be customized with decals if you want.

Whether it's a two-wheeled Blackbird or not, there are a few other benefits to the frame design. While some manufacturers hide their cabling inside the frame, the derailleur and chain are usually exposed. That's not the case here, with the drivetrain fully enclosed and protected from the elements, although we're not sure how that setup will go when it comes time for the annual service suggested by the company.

Ditching the spokes and running with solid polymer airless tires might make for a unique design, but it also frees up some space where the spokes used to be. Cyclotron wants to use that space for cargo or children, making its bike more practical than it would otherwise be. At the moment, there are three accessories available for those utility slots, including shopping baskets and a clever snap-in child seat.

In keeping with the futuristic frame design, there's a futuristic powertrain available for this sci-fi bike. As well as more traditional 12- and 18-speed manual setups, there's a electronic sequential gearbox available. Shifting in less than 0.2 seconds, the gearbox works at standstill or under full load and can shift for itself. Electric gearbox-equipped bikes will weigh just 11.6 kg (25.57 lb), making them 100 g (3.5 oz) heavier than the manual 12-speed version, but 200 g (7 oz) lighter than the 18-speed manual.

Enough of the boring practical bits, what the story with those lights? When darkness falls, a sensor automatically activates the LED wheel halos and laser-lane display, in an attempt to make the rider easy to see on unlit streets in the dead of night. We'd say it works, too, with those Tron-style wheels being hard to miss. Power comes from an integrated lithium-ion battery good for eight hours that is charged by an inbuilt dynamo, although the battery can be charged from a wall socket as well.

Continue reading and view the video here

Palace of the Alhambra, Spain

By: Charles Nathaniel Worsley (1862-1923)

From the collection of Sir Heaton Rhodes

Oil on canvas - 118cm x 162cm

Valued $12,000 - $18,000

Offers invited over $9,000

Contact: Henry Newrick – (+64 ) 27 471 2242

Mount Egmont with Lake

By: John Philemon Backhouse (1845-1908)

Oil on Sea Shell - 13cm x 14cm

Valued $2,000-$3,000

Offers invited over $1,500

Contact: Henry Newrick – (+64 ) 27 471 2242